Total Hydrocarbon (THC) Analysis in Medical Devices – Technical Principles, Device Construction and Validation Criteria

Total Hydrocarbon (THC) Analysis in Medical Devices – Technical Principles, Device Construction and Validation Criteria

Contents

1. Purpose of THC Analysis in Medical Devices

Total Hydrocarbon (THC) analysis is essential to identify volatile and semi-volatile organic compounds (VOCs) that may leach from medical devices into the patient environment. These compounds may originate from:

-

Lubricants, silicone oils, mold release agents

-

Residual solvents (IPA, hexane, toluene, xylene)

-

Ethylene oxide (EO) sterilization by-products

-

Packaging material emissions

-

PVC, PU, PE, PP, silicone, TPU polymer degradation products

THC analysis is directly related to ISO 10993-18 (Chemical Characterization) and ISO 10993-17 (Toxicological Risk Assessment).

2. Applicable Standards and Guidelines

| Standard / Regulation | Scope |

|---|---|

| ISO 10993-18 | Chemical characterization of medical device materials |

| ISO 10993-12 | Sample extraction (surface area/volume ratio, solvent selection) |

| ISO 10993-5 | Cytotoxicity testing of extracts |

| USP <467> | Residual solvent limits |

| TS EN 12619 / EPA 25A | THC/VOC measurement using Flame Ionization Detector (FID) |

| ISO 13485 / FDA 21 CFR 820 | Process control and documentation |

3. Analytical Technique – FID-Based THC Measurement

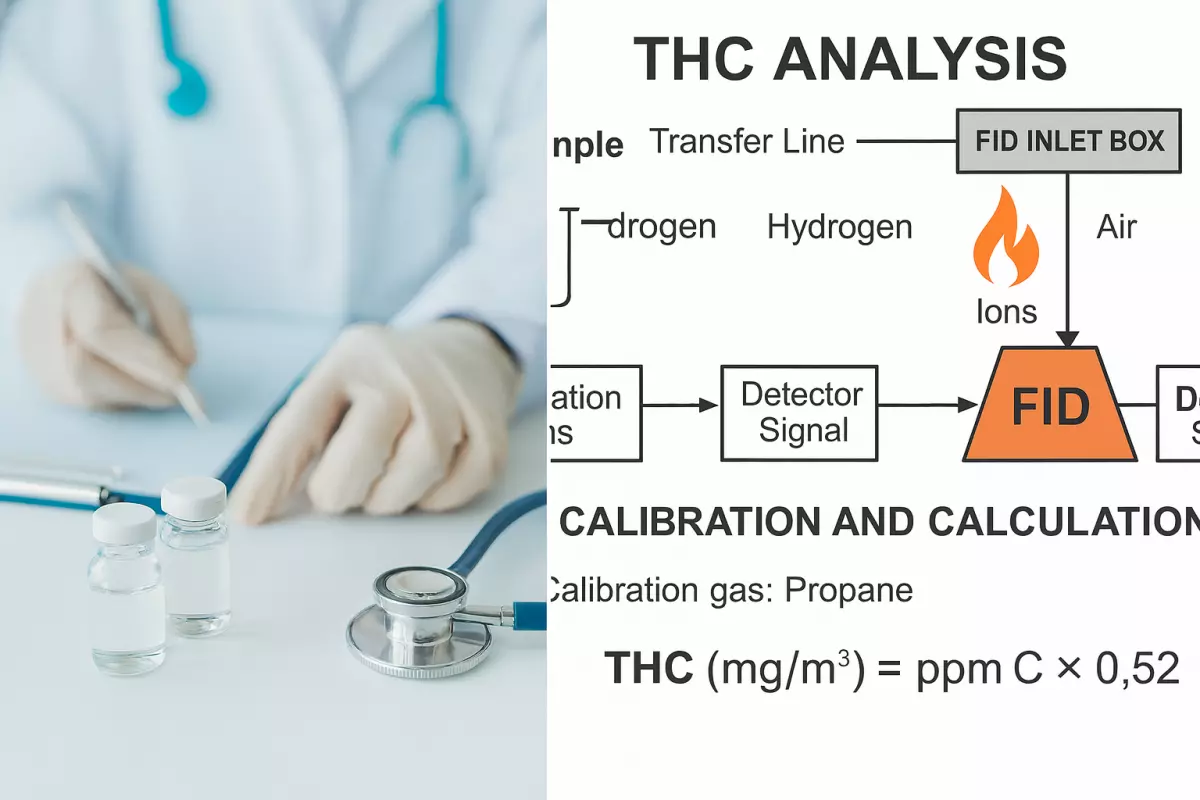

Flame Ionization Detector (FID) Principle

FID detects organic compounds containing C–H bonds by combusting them in a hydrogen-air flame, producing ions. The ion current is proportional to the hydrocarbon concentration.

| Parameter | Description |

|---|---|

| Flame Gas | Hydrogen + Synthetic Air |

| Detection Limit (LOD) | ~0.05 ppmC |

| Quantitation Limit (LOQ) | ~0.1 ppmC |

| Output Units | ppmC (carbon equivalent), mg/m³ |

4. Sample Preparation – According to ISO 10993-12

| Parameter | Specification |

|---|---|

| Extraction Ratio | 6 cm²/mL (surface area-based extraction) |

| Extraction Media | 0.9% NaCl, Ethanol 70%, PBS, IPA |

| Extraction Temperature | 37°C or accelerated at 50°C |

| Duration | 24–72 hours |

| Filtration | 0.22 μm PTFE filter (low VOC adsorption) |

5. Gas Chromatography – FID Method

GC-FID Operating Conditions

| Setting | Value |

|---|---|

| Column | DB-624 (30 m x 0.32 mm x 1.8 μm) |

| Carrier Gas | Helium (1.5 mL/min) |

| Injection Volume | 1 μL (Split 1:20) |

| Injector Temp. | 200°C |

| Oven Program | 40°C → 200°C at 10°C/min |

| Detector (FID) Temp. | 250°C |

| Hydrogen Flow | 40 mL/min |

| Air Flow | 450 mL/min |

6. Calibration Procedure

Calibration Standards

| Gas Standard | Concentration | Certification |

|---|---|---|

| Propane (C₃H₈) | 1% ±1% | ISO 6142 certified |

| Methane (CH₄) | 1% | Alternative carbon reference |

| Zero Air | Hydrocarbon-free | Baseline correction |

THC Calculation (ppmC to mg/m³)

Example:

Measured Value: 20 ppmC (Propane equivalent)

7. Acceptance Limits for Medical Devices

| Parameter | Limit | Reference |

|---|---|---|

| Total Hydrocarbon Residue | < 10 mg/device | ISO 10993-12 & FDA |

| Residual Solvents (IPA, Hexane) | < 500 µg/device | USP <467> |

| THC in Sterilization Chamber | < 50 ppmC | TS EN 12619 |

| EO Sterilization VOC Residue | < 250 µg/device | ISO 11135 |

8. Method Validation Criteria (FDA & ISO Requirements)

✔ System Suitability Test (SST) performed before analysis

✔ Blank measurement (zero air) < 0.1 ppmC

✔ Linearity: R² ≥ 0.995

✔ Repeatability: RSD < 5%

✔ Recovery: 80–120% (spiked QC samples)

✔ Positive Control: Heptane or Toluene standard solution

9. Reporting Requirements

A compliant test report must include:

-

Sample description (material, batch number, sterilization type)

-

Extraction conditions (time, temperature, solvent, SA/V ratio)

-

GC-FID chromatograms and calibration curves

-

Raw THC values (ppmC) and converted values (mg/m³, µg/device)

-

Comparison with ISO/FDA limit values

-

Risk assessment according to ISO 10993-17

-

Conclusion: Complies / Does Not Comply