What Are Biocompatibility Tests?

Biocompatibility tests are analytical evaluations that determine the interaction of medical devices with human tissues. These tests assess whether the device contains toxic substances and whether it causes damage to tissues or cells. ISO 10993 is an international standard that guides how biocompatibility tests should be conducted and which specific evaluations are required.

ISO 10993 Standard and Its Importance

The ISO 10993 standard is a comprehensive series that covers the biological evaluation of medical devices. It defines which biocompatibility tests should be applied according to the intended use and contact duration of the device. The key objectives of the ISO 10993 standard include:

-

Evaluating device safety

-

Minimizing potential health risks to users

-

Ensuring regulatory compliance

Types of Biocompatibility Tests

Some of the core tests performed under ISO 10993 include:

| Test Type | Purpose |

|---|---|

| Cytotoxicity Test | Detects toxic substances that may harm living cells. |

| Sensitization Test | Evaluates whether the device triggers allergic reactions. |

| Irritation Test | Determines whether the device causes irritation to skin, eyes, or mucosal tissues. |

| Acute Systemic Toxicity Test | Assesses short-term systemic toxic effects. |

| Hemocompatibility Test | Measures the interaction of blood-contacting devices with blood cells and coagulation systems. |

| Genotoxicity Test | Determines whether the device causes DNA damage. |

| Carcinogenicity and Reproductive Toxicity Tests | Evaluates long-term effects such as cancer risk or impacts on reproductive health. |

Which Medical Devices Require Biocompatibility Testing?

Biocompatibility tests are essential for the safety and compliance of the following devices:

-

Catheters, needles, and implants

-

Artificial organs and prosthetics

-

Surgical materials

-

Blood bags and tubing

-

Dental materials

-

Diagnostic devices

Stages of Biocompatibility Testing

-

Risk Assessment: Test requirements are determined according to the contact type (skin, blood, tissue, etc.) and duration.

-

Sample Preparation: Appropriate samples are taken from the device for testing.

-

Laboratory Testing: Tests are conducted according to ISO 10993 standards.

-

Evaluation of Results: Findings are analyzed, reported, and the biocompatibility of the device is concluded.

Advantages of Biocompatibility Testing

-

User Safety: Ensures that medical devices are safe for use.

-

Regulatory Compliance: Meets legal requirements for market approval of medical devices.

-

Market Access: ISO 10993 compliance facilitates global market acceptance.

-

Brand Reliability: Strengthens brand reputation by ensuring product safety.

ISO 10993 and Global Compliance

Biocompatibility testing is essential not only for local regulatory authorization but also for international certification. Authorities such as the FDA, CE Marking, and other global regulatory bodies require ISO 10993 compliance for medical device approval.

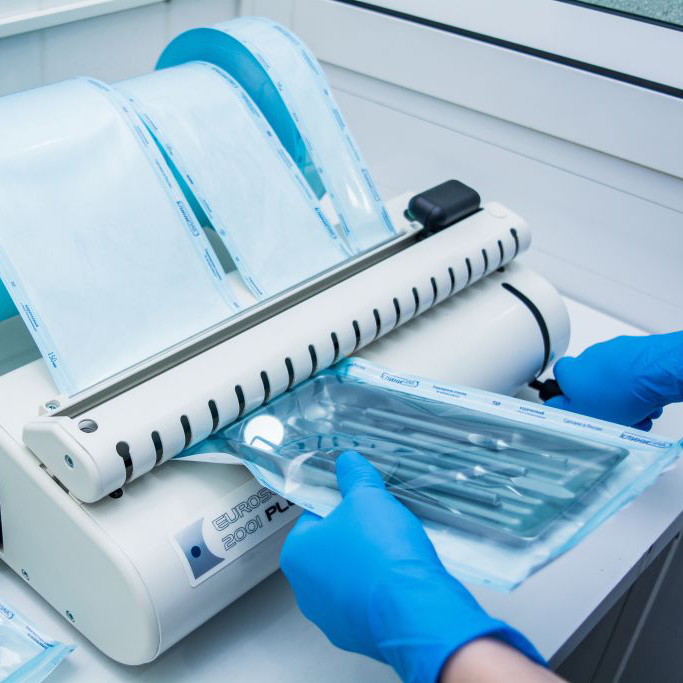

Sterility Test – ISO 11737-1

ISO 11737-1 Sterility Test is an international standard that determines whether medical devices are free from microbial contamination. This test specifically measures the bioburden, which is the number of viable microorganisms present on a product before sterilization.

ISO 11737-1 is critically important for:

-

Validating sterilization methods

-

Demonstrating the effectiveness of sterilization processes

-

Ensuring the microbiological safety of medical devices

Extractable & Leachable Volatile Organic Compounds (VOC) – ISO 10993-12 / 18 / 17

Determining VOCs released from medical devices is essential for safety, biocompatibility, and CE/FDA compliance. ISO 10993-12 defines sample preparation, ISO 10993-18 covers chemical characterization, and ISO 10993-17 evaluates toxicological risk. These processes ensure that any chemicals leaching from the device to the patient are identified and proven safe.

Surface Composition Comparison – ISO 10993-13 / ISO 10993-12 / ASTM E1252

Surface degradation products and chemical components released from medical devices are evaluated under ISO 10993-13. ISO 10993-12 defines sample preparation, while ASTM E1252 outlines spectroscopic techniques for surface chemical analysis. These methods enable comparative assessment of material compatibility, surface integrity, and potential biological risks.

Bacterial Endotoxin (LAL) Test – USP 161 / EP 2.6.14 / USP 85 / ISO 11737-3

The bacterial endotoxin test detects pyrogenic lipopolysaccharides in medical devices and injectable products. USP 85 and EP 2.6.14 specify the LAL method, USP 161 defines testing conditions, while ISO 11737-3 sets endotoxin limits for medical devices. The test is performed using gel clot, turbidimetric, or kinetic chromogenic techniques.

In Vitro Cytotoxicity Test – TS EN ISO 10993-5 / TS EN ISO 10993-12

The in vitro cytotoxicity test evaluates the effect of medical device materials on cell viability. TS EN ISO 10993-5 defines test principles, cell morphology assessment and viability measurement methods. TS EN ISO 10993-12 specifies sample preparation, extraction conditions and surface area-to-volume ratios. This test is a fundamental step in biocompatibility evaluation

Ethylene Oxide (C₂H₄O) Residual Determination – TS EN ISO 10993-7 Annex B

For medical devices sterilized with ethylene oxide, residual EO, Ethylene Chlorohydrin (ECH) and Ethylene Glycol (EG) levels are evaluated according to TS EN ISO 10993-7 Annex B. The standard defines acceptable daily exposure limits, aeration requirements, and GC-MS analytical methods. The goal is to ensure EO residues do not pose toxic or carcinogenic risks to patients.